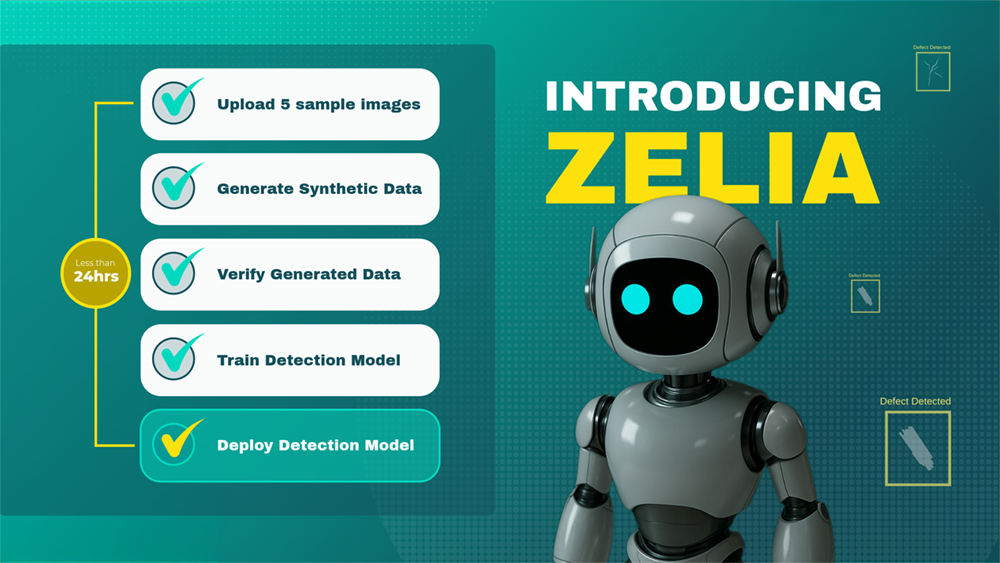

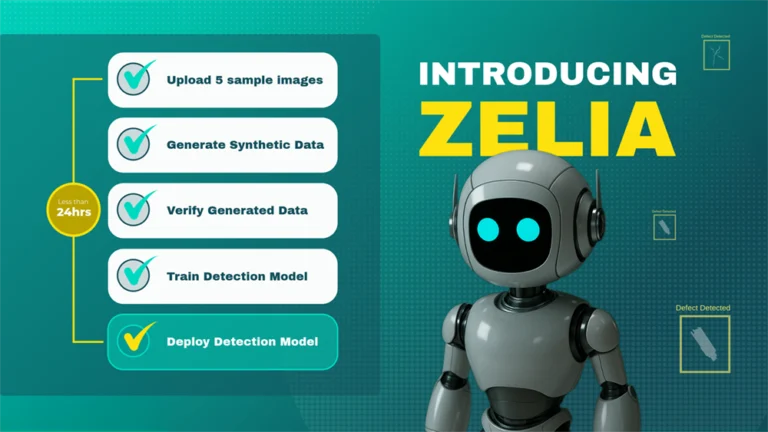

January 2026 – Zetamotion today announced the launch of ZELIA, a new end to end learning and inspection assistant that enables manufacturers to train defect detection models using as few as five clean samples and five defect images.

The platform addresses one of the most persistent challenges in industrial AI inspection: the lack of defect data during new product launches. By combining generative AI with automated validation, ZELIA allows teams to deploy inspection models in hours rather than weeks.

Turning the cold start problem into a practical workflow

In traditional quality inspection projects, engineers must wait for rare defects to appear before models can be trained. This delays automation, slows ramp up, and often forces continued reliance on manual inspection.

ZELIA was designed to remove that bottleneck. Users begin by uploading a minimal set of reference images. From there, the system generates synthetic defect data, verifies it, trains detection models, and prepares them for deployment in a single guided workflow.

According to Zetamotion CEO Wilhelm Klein, the goal was to make advanced inspection accessible without lengthy data collection cycles.

“Deploying a new defect detector has always meant waiting for the right failures to happen,” Klein said during the launch webinar. “With ZELIA, we can start from intent rather than accident, and that changes how fast teams can move.”

Generative AI as an inspection accelerator

At the core of ZELIA is a multi agent architecture that orchestrates data generation, validation, and training through natural language instructions. Engineers can describe what they want to inspect, while the system handles the complexity of creating robust training data.

Zetamotion’s AI research team describes this approach as a way to convert scarcity into abundance. Instead of relying on historical defects, the platform synthesizes and validates data that reflects real world variability from day one.

“We set out to solve the industrial cold start problem with generative AI” said Nguyen Phuong Anh, AI Research Lead at Zetamotion. “ZELIA acts like an on demand synthetic data factory, cutting onboarding from weeks down to hours.”

Built for manufacturing reality

During the launch webinar, Sales and Creative Lead Mike Kurzewski emphasized that ZELIA was shaped by real production constraints rather than lab conditions.

“Manufacturers do not have the luxury of perfect datasets,” Kurzewski said. “ZELIA meets teams where they are, with minimal inputs and clear steps that fit into existing inspection workflows.”

The platform is designed to integrate with Zetamotion’s broader inspection ecosystem, supporting verification, model approval, and deployment without requiring extensive retraining cycles.

Availability

ZELIA is available now as part of Zetamotion’s end to end learning and inspection offering. Manufacturers interested in early access can learn more and register their interest at https://zetamotion.com/zetamotion-end-to-end-learning-inspection-assistant/.