Your Shortcut to Robust Inspection Models

Synthetic data isn’t just a tool. It’s the foundation of how we make deep learning work for real-world inspection challenges.

Deep learning thrives on variation not just volume. With synthetic data, we can simulate thousands of realistic defect scenarios, even when real-world samples are limited. It’s how we build models that actually work in messy, real factory conditions.

What is synthetic data and why we use it?

Synthetic data is artificially generated visual data that mimics real-world inspection scenarios — defects, lighting, texture — without needing thousands of physical samples. It’s how we overcome data scarcity and build AI models that generalize better, faster.

Augments or replaces limited real data: ideal for rare defects or lower volume production

Eliminates manual labeling: every defect is generated with automatic masks, labels, and metadata built-in

Fully controlled & scalable: lets us simulate variations, edge cases, and inspection environments with precision

How we curate your dataMeet ZELIA: Your New AI Quality Inspection Assistant

Discover the new Zetamotion pipeline & assistant that turns a few sample images into a fully curated synthetic dataset and trains your AI vision inspection model for you. Faster, adaptive, and effortless.

Synthetic variants eliminate manual labelling

By generating every image and its defect annotations at runtime, our synthetic data pipeline eliminates manual labeling entirely. Instead of spending hours—or days—drawing masks and tagging samples, each defect variant comes pre‑labeled with pixel‑perfect masks and metadata. That means faster dataset creation, no human bias in annotations, and a training set that’s both accurate and instantly ready for deep‑learning workflows.

Key Benefits

Faster model training

Better generalization on rare defects

Lower false‑positive/negative rates

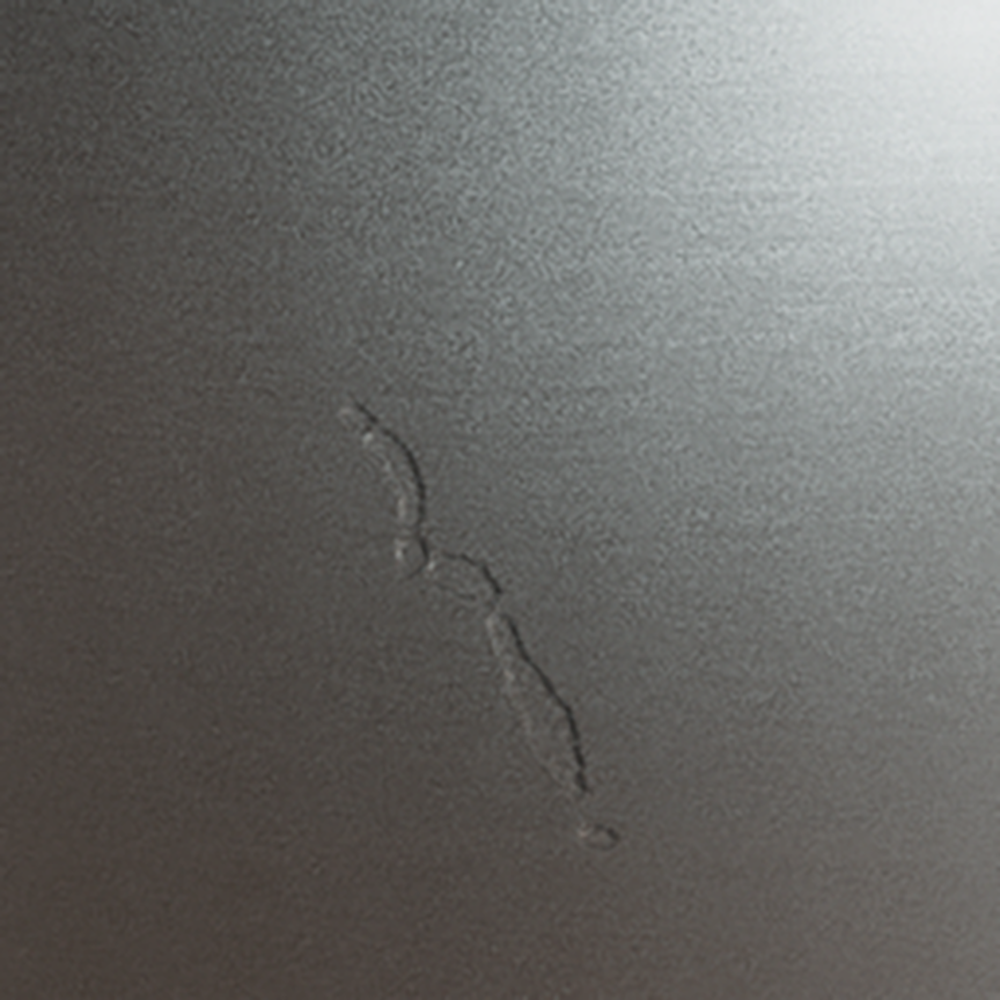

Synthetic variants

Synthetic data variations of defects on a bitumen/asphalt surface texture

Read moreSynthetic data questions

It’s computer‑generated imagery that mimics real products, lighting, and defects. Each image is auto‑labeled with pixel‑perfect masks, giving AI thousands of training examples without manual annotation.

Synthetic data vs Real dataIt excels when defects are rare, every part is slightly unique, or you’re launching a new variant with no historical failure data. Synthetic samples fill those gaps fast. It particularly helps reduce resource drain in with regards to time and manpower.

Succeeding with Synthetic dataWhen paired with a small set of real images for calibration, Spectron‑trained models routinely achieve extremely high levels of accuracy. It helps us deploy quickly and iterate efficiently when coming across outliers or edge cases.

Data curation & AIA single high‑resolution scan, CAD, or even calibrated photos are enough. We often beign with a simple defect catalogue and a handful of sample images. Our engine extrapolates geometry, textures, and defect physics from that baseline.

Manufacturing service