Spectron™ AI Quality Control

Automate defect detection, streamline reporting, and deploy at line‑speed all from one modular platform.

Spectron’s goal is simple: deliver lightning‑fast inspection that adapts as quickly as your production line evolves.

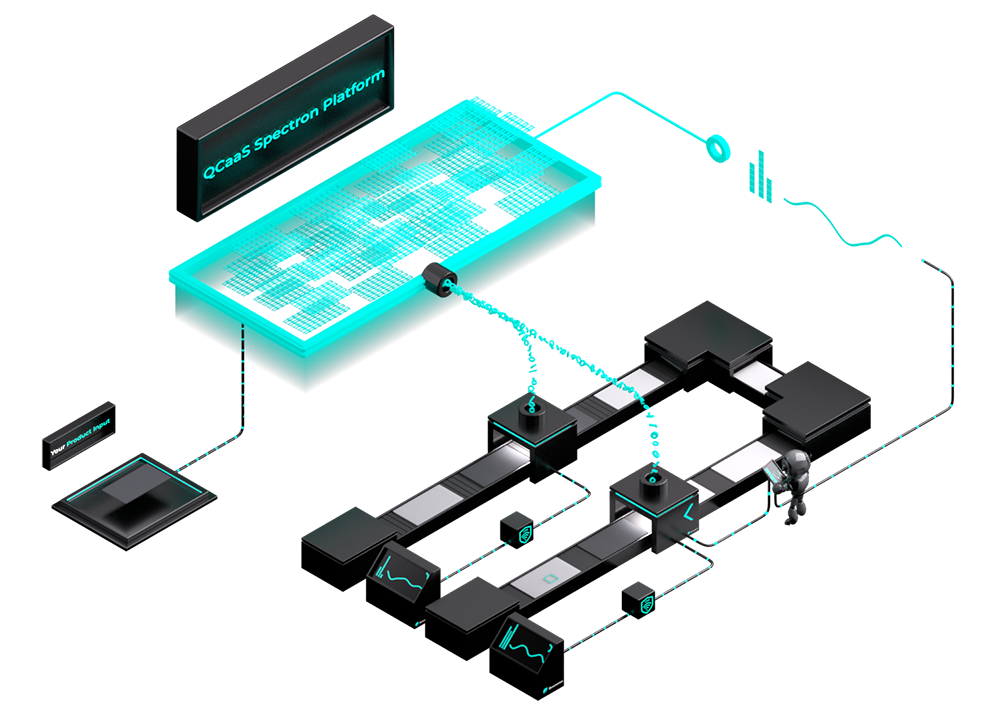

An end-to-end solution

Think of us as your embedded AI team eliminating your implementation headaches. We take care of the heavy lifting, so you don’t have to.

Data Curation & AI Model Training

We take care of preparing the right data to train high-performing AI models tailored to your products.

Curated synthetic defect data

Fully trained inspection-ready AI models

No manual labeling needed from your team

Data CurationPlatform Setup & Configuration

We configure Spectron to match your inspection flow, reporting needs, and defect criteria avoiding one-size-fits-all setups.

Custom inspection specs and thresholds

Real-time dashboard and reporting setup

Support for multiple products and lines

Platform ConfigHardware Sourcing & Deployment

We source and install the right hardware so your system runs smoothly in your factory, not just in theory.

Industrial cameras and compute units

On-site deployment and calibration

Works on-prem or offline, no cloud required

Hardware DesignWhy Spectron Works When Others Stall

Spectron was built with manufacturers, for manufacturers. We’re eliminating the blockers that make traditional vision systems stall.

Tailored AI Team

Guaranteed Results

Expertise capture and preservation

Days‑to‑Deploy

Why choose Spectron

Spectron brings together data, configuration, and hardware into a single, adaptable toolkit engineered to drop into your line with minimal disruption and start adding value from day one.

Synthetic‑data engine means faster onboarding & higher accuracy

Human‑in‑the‑loop feedback keeps models improving

Expertise capture and preservation

On‑premise inference protects your data and uptime