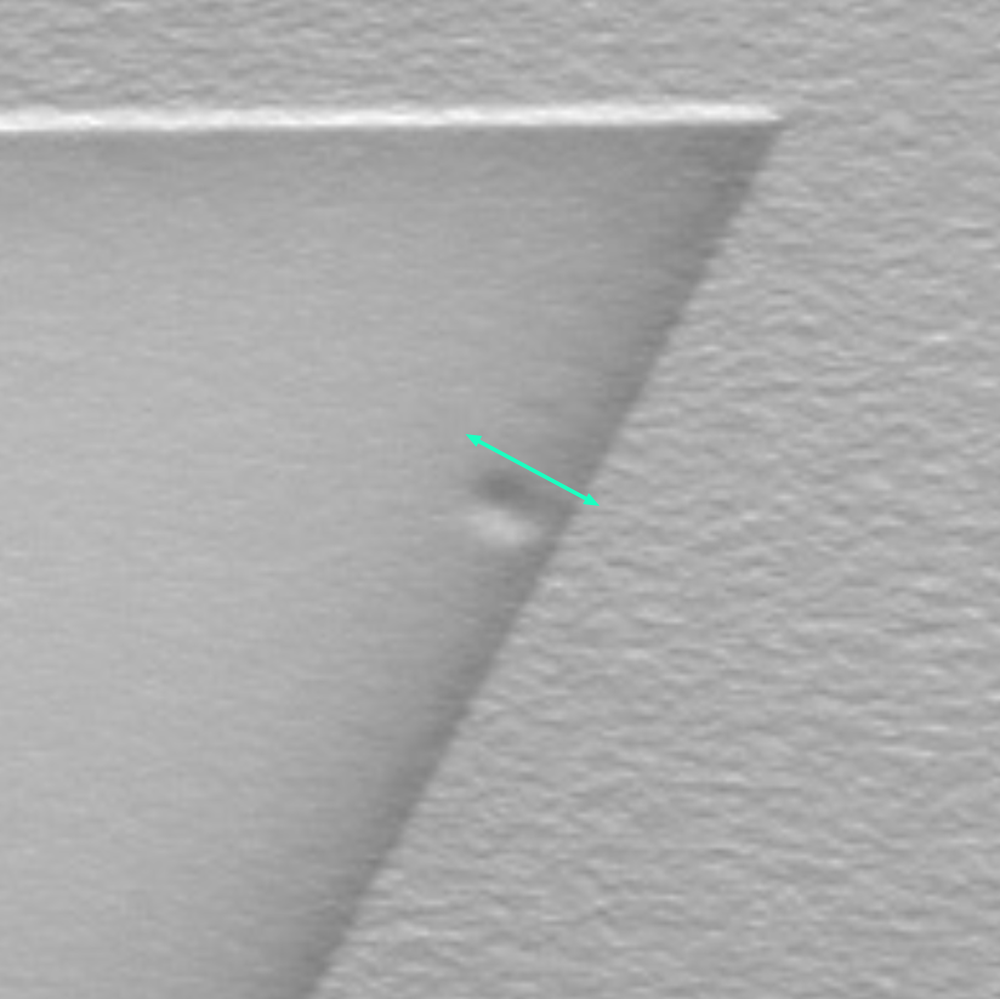

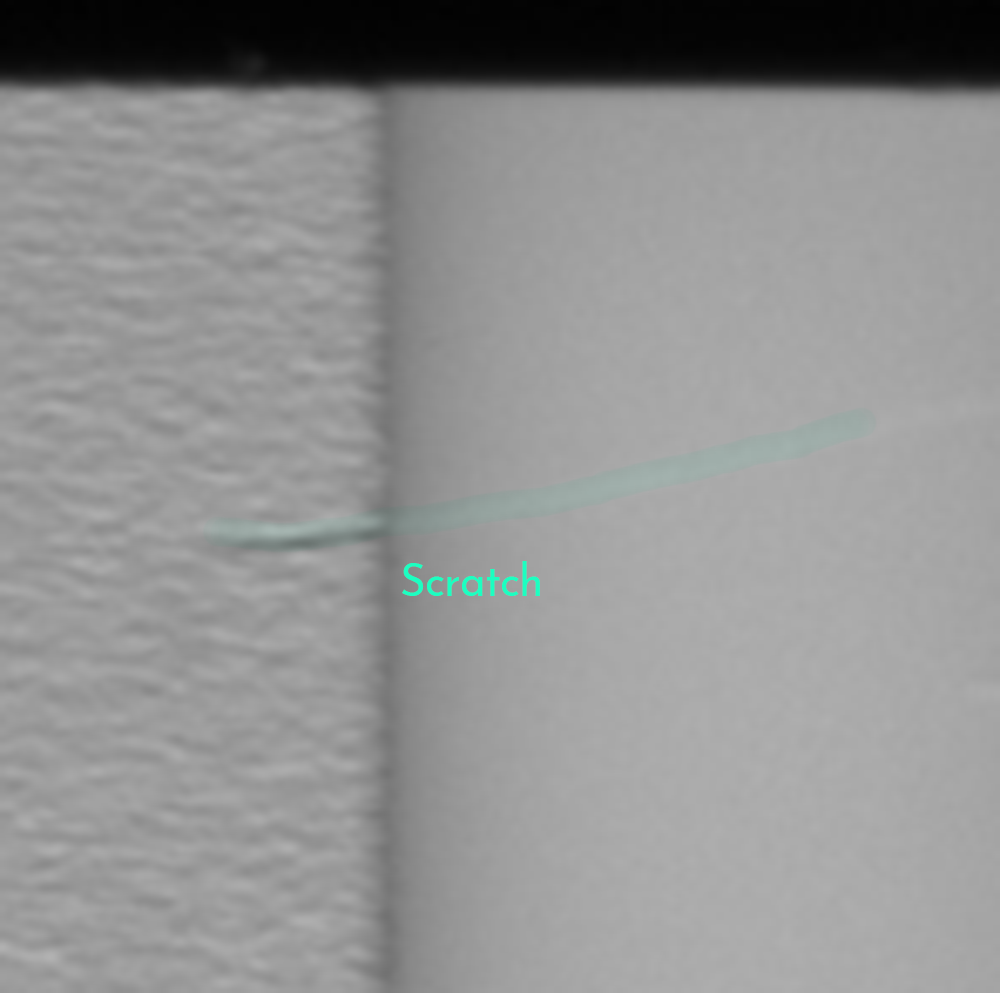

Defect Detected

Detect

0.5mm x 0.25mm

Measure

Crack Defect

Classify

Output all results in a customized report to match your internal procedures

Where We Make the Difference

Traditional inspection systems struggle where real-world manufacturing gets messy. Zetamotion specializes in solving inspection challenges that are too complex, too rare, or too variable for off-the-shelf solutions.

Lasting Partnerships

We understand that production lines evolve. Be it new materials, production methods, a new product line or new defect standards to be met – Zetamotion co-evolves with you and ensures lasting automated QC

Your QC Hub

With Zetamotion’s SpectronTM platform you have access to all things QC on your production line. Onboard products, look up reports, live-monitor several production line yield points and cross-correlate the data for predictive & prescriptive troubleshooting and maintenance all in one place

Real People, Real Care

Where other tools are faceless, often, leaving you to your own devices. We have full support integrated into our platform. With intuitive, instant, feedback and comment functions as well as a team on hand 24/7 we ensure flawless processes

Commonly asked questions

We design or retrofit hardware stations, integrate lighting and triggers, install edge compute, train the AI model, validate accuracy on‑site and offer 24/7 on-going support with continuous improvements along the way.

Spectron overviewWe can get started in as little as 2 weeks. A single‑line project, from assessment to full production sign‑off, averages 4–6 weeks depending on factory access and safety approvals.

In most cases, yes. We support GigE, USB3, CoaXPress, and many smart‑camera SDKs. If your sensor meets the resolution spec, we reuse it. This also speeds up deployment as hardware sourcing is not needed.

Hardware sourcing & deploymentA maintenance SLA covers model updates, remote diagnostics, and quarterly performance reviews; urgent issues receive a response within 24 hours. We also help onboard new product variants in under 24hrs and work to ensure you achieve your quality goals.

Thanks to synthetic data and quick change‑overs, it does indeed pay off, especially where rework or warranty costs are high.