Transitioning to AI and automation in quality control can be daunting for manufacturers. The process often comes with questions about feasibility, compliance, data security, and the right approach to implementation. With so much at stake, it’s essential to start with a solid foundation. This guide is designed to help you navigate the initial stages of implementing AI in quality control, highlighting what to look out for and offering a clear roadmap from concept to compliance. Whether you’re just exploring or ready to take the first step, these strategic insights will set you up for a smooth, effective AI journey in quality control.

Step 1: Start Small with Either a Proof of Concept (PoC) or a Proof of Principle (PoP)

Starting with a small-scale project is a strategic way to test AI quality control without fully committing resources. Depending on your needs, you can choose between a Proof of Principle (PoP) or a Proof of Concept (PoC).

Option 1: Proof of Principle (PoP)

A PoP demonstrates AI’s potential benefits off-site, without impacting production. It provides a preview of the approach and expected outcomes, allowing you to explore AI’s value with zero disruption.

Option 2: Proof of Concept (PoC)

If you’re ready to test AI on-site, a PoC applies the technology to a specific quality control task on your production line. This setup allows you to evaluate real-time results, such as defect detection accuracy and cost savings, and helps gauge how AI integrates with existing processes.

Starting with either option provides a low-risk, data-driven foundation for scaling AI in quality control, helping you make informed decisions before a full deployment.

Step 2: Address Regulatory Requirements Early

Ensuring regulatory compliance is essential when implementing AI in quality control, particularly in heavily regulated industries like pharmaceuticals. Proactively addressing standards reduces the risk of costly delays and establishes a solid foundation for compliant AI deployment.

Key Steps to Ensure Compliance

Identify Relevant Standards: Determine applicable standards, such as ISO 9001 for quality management and specific pharmaceutical regulations from bodies like the FDA or EMA.

Engage Early with Regulatory Bodies: Proactively consult with regulators to clarify AI requirements, ensuring alignment with industry benchmarks from the outset.

Document System Performance: Maintain thorough records of AI performance, accuracy, and data handling practices to simplify compliance reviews and audits.

Plan for Ongoing Audits: Regulatory standards evolve, so scheduling regular audits and updates keeps your AI system in line with new guidelines.

Example

A pharmaceutical manufacturer can work with the FDA or EMA to ensure their AI system meets regulatory thresholds for accuracy and documentation, simplifying future audits and supporting consistent, compliant performance.

Proactively addressing compliance not only minimizes setbacks but builds stakeholder confidence and lays a strong foundation for integrating AI into quality control.

Step 3: Leverage System Freeze Capabilities for Consistency

System freeze capabilities allow you to “pause” your AI system at peak performance, creating a stable baseline for updates and troubleshooting. This feature ensures consistent results across your organization, especially as you scale or adjust settings.

Why Use System Freeze?

Lock in Key Metrics: Freeze settings at desired defect rates or inspection speeds to maintain consistency.

Unified Standards: Ensure all teams work from the same benchmarks, simplifying collaboration.

Controlled Testing: Freeze points let you test new configurations without risking overall AI performance.

Example

A manufacturer aiming for a 1% defect rate can freeze the AI at this level. If updates cause deviations, they can revert to the original frozen settings to quickly restore stability.

System freeze capabilities provide a reliable foundation, helping manufacturers keep quality consistent during scaling or system updates.

Step 4: Regularly Perform Measurement System Analysis (MSA)

Regular Measurement System Analysis (MSA) ensures your AI’s accuracy and consistency by detecting any performance drift over time.

Key Steps for Effective MSA

Set Regular Intervals: Schedule MSA checks based on production demands.

Focus on Key Metrics: Track accuracy and repeatability to maintain quality standards.

Document Results: Keep records to monitor system stability and support compliance.

Example

In surface defect detection, MSA might reveal slight shifts in accuracy. Early identification allows quick recalibration, ensuring continued precision.

MSA maintains your AI’s reliability, helping it consistently meet quality requirements even as conditions change.

Step 5: Implement Robust Cybersecurity Measures

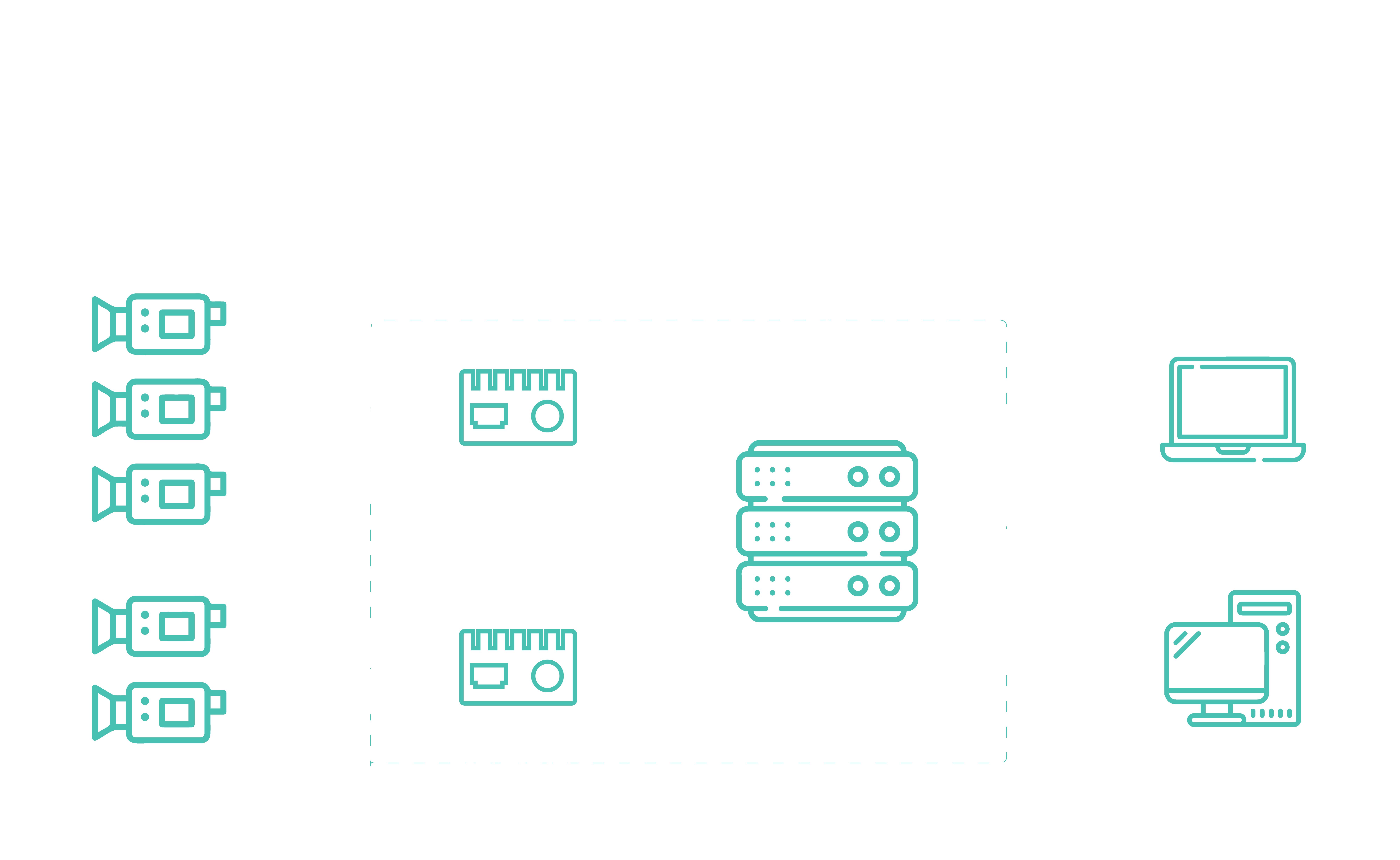

Securing your AI quality control system is essential to protect data integrity and ensure consistent, reliable performance. Zetamotion offers multiple cybersecurity solutions, including on-premises inspection options, to help you tailor data protection according to your needs.

Key Cybersecurity Practices

On-Premises Inspection Options: Conduct quality control entirely on-site to keep sensitive data within your facility, reducing exposure to external threats.

Adopt ISO-Compliant Protocols: Follow standards like ISO 27001 to maintain strong data protection.

Data Encryption: Use encryption for secure data transfer, especially when cloud storage is involved.

Regular Security Audits: Schedule audits and updates to proactively address any vulnerabilities.

Example

For manufacturers handling sensitive product data, Zetamotion’s on-premises inspection option can provide enhanced security by keeping data local, while regular encryption and audits ensure robust protection if cloud access is required.

With these measures, you can trust that your AI system will operate securely, maintaining data privacy and system reliability.

Step 6: Plan for Seamless Integration with Existing Systems

A critical factor in adopting AI for quality control is ensuring it integrates smoothly with your existing setup. Zetamotion’s solutions are designed to work flexibly with a wide range of hardware, software, and sensors, making it easy to incorporate AI without disrupting established workflows.

Our platform can connect seamlessly to your current infrastructure, whether you use specific sensors, cameras, or ERP and SCADA systems. This compatibility means Zetamotion’s AI can enhance your quality control processes without requiring extensive reconfiguration or new equipment investments.

Example

For a manufacturer with existing vision systems and data management software, Zetamotion’s platform can directly integrate, leveraging existing hardware while providing advanced AI-driven insights. This compatibility minimizes downtime and enables a quick transition to automated quality control.

By prioritizing seamless integration, Zetamotion ensures that adopting AI is a straightforward process, maximizing efficiency without disrupting production.

Conclusion

Integrating AI into quality control can be transformative for manufacturers, but it requires a strategic approach to maximize effectiveness and minimize disruption. By starting with a tailored Proof of Concept or Proof of Principle, addressing regulatory needs from the outset, leveraging system freeze capabilities, conducting regular Measurement System Analysis, and ensuring robust cybersecurity, manufacturers can set the stage for successful AI implementation. Zetamotion’s solutions further support seamless integration, allowing AI to complement and enhance existing systems effortlessly.

AI-driven quality control offers unparalleled precision, consistency, and efficiency—key benefits for manufacturers looking to stay competitive in today’s demanding market. With a thoughtful approach and the right tools, manufacturers can confidently embark on their AI journey, knowing they are set up for success.