In industries like aerospace, electronics, and automotive, AI-driven inspection is becoming essential to sustainable manufacturing. Our feature in the Electronics Era article “Sustainable Precision: Cutting Waste and Boosting Efficiency with AI-Driven Inspection” describes how traditional quality control methods routinely stall at about 80 % defect detection accuracy—far short of the 99 %+ levels required in many high-stakes sectors.

Material gets scrapped unnecessarily, energy is wasted in rework or over-inspection, and production lines stall when models need to be retrained or data relabelled. The article argues that synthetic data, faster variant adaptation, and more robust inspection models are key tools for closing that “last-mile” gap in defect detection.

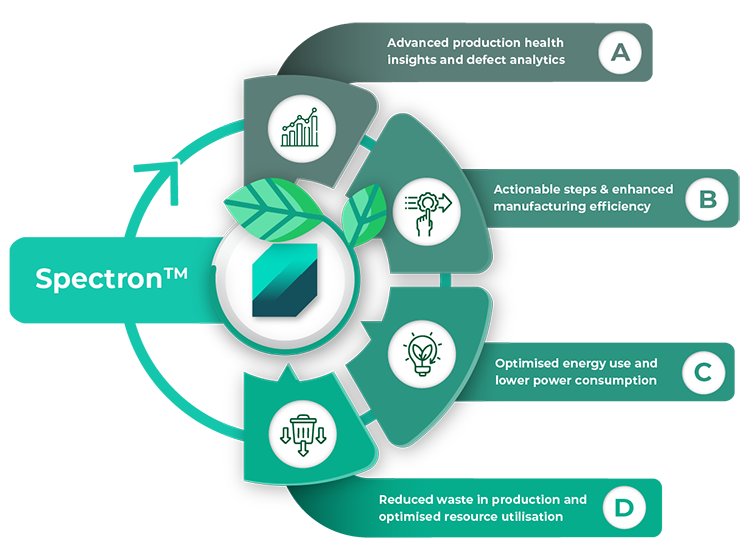

At Zetamotion, we’ve seen how platforms like Spectron can leverage a single scan of a good part to generate synthetic defect examples, speeding system training while avoiding huge datasets of real defects. Internal validation ensures that models don’t drift when conditions change—lighting, surface finish, or product variants. Our Spectron platform is explicitly designed to support manufacturers in making inspection both precise and sustainable.

Efficiency gains translate directly into sustainability: less energy use, less scrap, faster changeovers, and reduced labour for inspection. For manufacturers considering vision inspection, our manufacturing inspection service helps with pilot deployment, data strategy, and synthetic-data-augmented model training to achieve both high accuracy and reduced waste.