Hardware Design & Deployment

Tailored inspection hardware setups. Hardware that fits your line and your needs, not the other way around.

Assess Your Inspection Parameters

We start by understanding your inspection needs so we can recommend the right setup.

Evaluate required resolution and scan area based on your defect types

Assess throughput, product handling, and environmental constraints

Match inspection goals to hardware performance specs

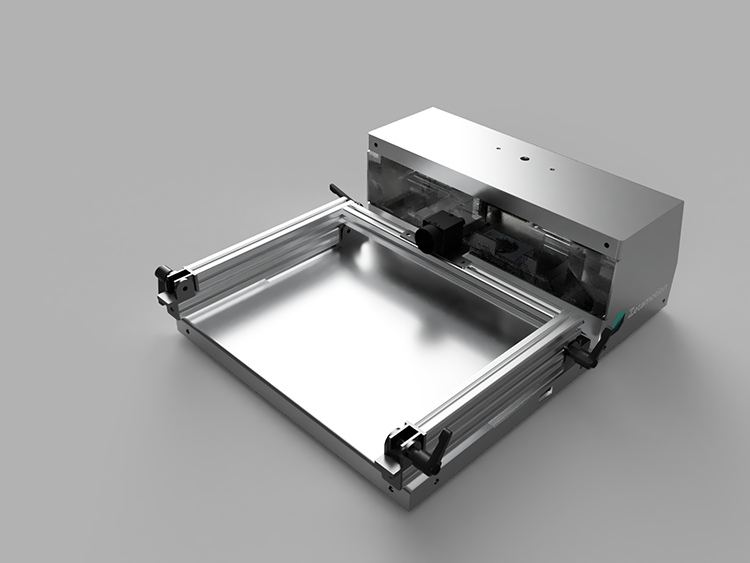

Design an Inspection Station

Our team designs a custom inspection station that aligns with your workflow to ensure reliable capture.

Camera and lighting selection for your material and surface type

Sensor positioning and mounting design

Compute hardware (on-edge or industrial PC) matched to your performance needs

Source, Integrate & Deploy

We ensure Spectron works seamlessly with your existing line. Fast setup, minimal disruption.

On-site deployment with minimal disruption

Calibration and tuning for lighting, alignment, and performance

Ongoing support to ensure uptime and long-term reliability

Hardware-Agnostic. Deployment-Ready.

Whether you’re retrofitting an existing station or building from scratch, we ensure smooth setup and reliable performance.

Compatible with leading industrial cameras, 3D sensors, line scan and area scan systems

Support for GigE Vision, USB3 Vision, and custom interfaces

Open protocols and modular architecture ensure interoperability