If you’ve worked in manufacturing, you know the frustration of trying to implement AI-powered inspection systems.

It always sounds promising—automate quality checks, boost accuracy, reduce waste—but the reality often feels like an endless slog.

First, you’re told you need thousands of sample images.

Then you discover every image requires manual labeling that eats up time and resources.

And before you know it, the project that was supposed to transform your production line drags on for months or even years, leaving you wondering if it will ever work.

At Zetamotion, we believe manufacturers deserve better. That’s why we created Spectron™, a turnkey solution for automated quality inspection that eliminates the most painful parts of traditional AI deployment.

Here’s how Spectron™ rewrites the story—and why more manufacturers are adopting it to improve efficiency and achieve near-perfect accuracy.

From Thousands of Sample Images to One Scan

With conventional approaches, collecting training data can bring your plans to a halt before you even begin.

Legacy AI inspection systems require thousands of product images to train their models properly.

Spectron™ takes a smarter route.

With just one scan, you can start building a high-precision inspection model.

This streamlined approach to synthetic data generation means you can skip the endless data collection phase and start seeing results faster.

No Manual Labeling Required

Traditional AI inspection platforms rely on manual data labeling—an incredibly time-consuming process that demands 20–30 seconds per image.

Multiply that by thousands of images, and you’re looking at weeks of tedious work before your system can even begin learning.

Spectron™ completely eliminates manual labeling.

Our AI automatically learns from the scan you provide, leveraging semantic understanding to train itself accurately.

No more wasting resources labeling images by hand.

Faster Time to Deploy AI-Powered Inspection

When you invest in AI quality control, you shouldn’t have to wait years to see value.

Old-school solutions typically require months to years to deploy, with constant delays and unexpected obstacles.

Spectron™ is built for speed.

Most customers can deploy the system in weeks to a few months, accelerating your path to ROI and improved defect detection.

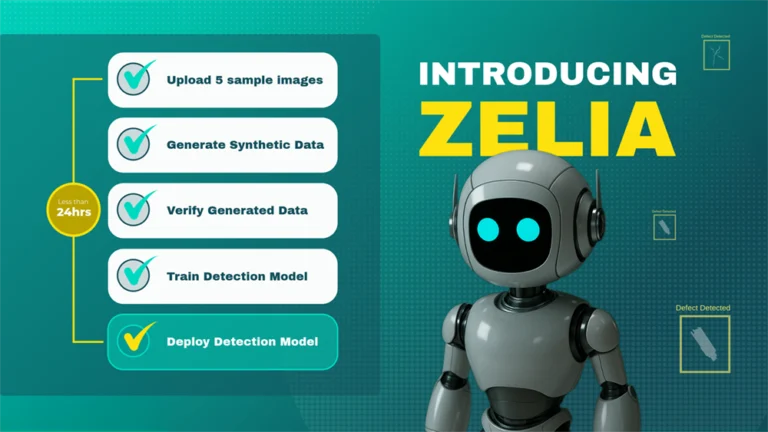

24-Hour Product Variant Onboarding

Manufacturers often struggle when introducing new product variants into their inspection process.

With conventional systems, adding a new variant means retraining models over several weeks.

Spectron™ simplifies variant onboarding to just 24 hours. Whether you need to inspect 1 product or 100, our AI evolves instantly to keep your production agile.

Guaranteed Performance and Accountability

One of the most frustrating parts of implementing AI in manufacturing is the finger-pointing when something goes wrong.

In most cases, responsibility is externalized to you—if the system doesn’t meet expectations, you’re left to figure it out alone.

Spectron™ does it differently. We internalize ownership and guarantee performance and accuracy. That means if there’s a problem, we stay with you until it’s solved.

A True Manufacturing Partnership, Not a Transaction

Many AI providers sell a one-off software license, provide minimal support, and disappear once you sign the contract.

At Zetamotion, we believe in building co-evolving partnerships. When you adopt Spectron™, you get a dedicated partner with a clear ROI guarantee that adapts as your needs change.

A Turnkey AI Quality Control Solution

Most AI inspection systems are either software-only or hardware-only, forcing you to piece together multiple solutions.

Spectron™ is a turnkey AI-powered inspection platform that includes everything you need:

No more compatibility issues, no more chasing vendors—just a complete solution that works out of the box.

Ready to Rethink AI Inspection?

Manufacturers across industries are transforming their production with Spectron™, achieving higher efficiency, lower waste, and more consistent product quality.

Don’t let outdated processes hold your business back. Contact us today to see how Spectron™ can help you implement fast, reliable, AI-powered quality control—without the headaches.