In today’s competitive landscape, quality control is evolving beyond traditional methods, especially with the rise of AI-driven inspection. It’s not just about spotting defects anymore — it’s about understanding them in context. As with many areas of machine learning, context plays a pivotal role in accurate interpretation and decision-making.

Our software, Spectron™, uses advanced semantic teaching capabilities to enable AI inspection systems to quickly and accurately distinguish between minor and critical defects, assessing each one based on its real-world impact.

In this post, we’ll explore how our quality control platform combines semantic teaching with synthetic data generation to provide a powerful, scalable quality control solution for manufacturers and inspection companies alike.

How Semantic Teaching and Synthetic Data Work Together at Zetamotion

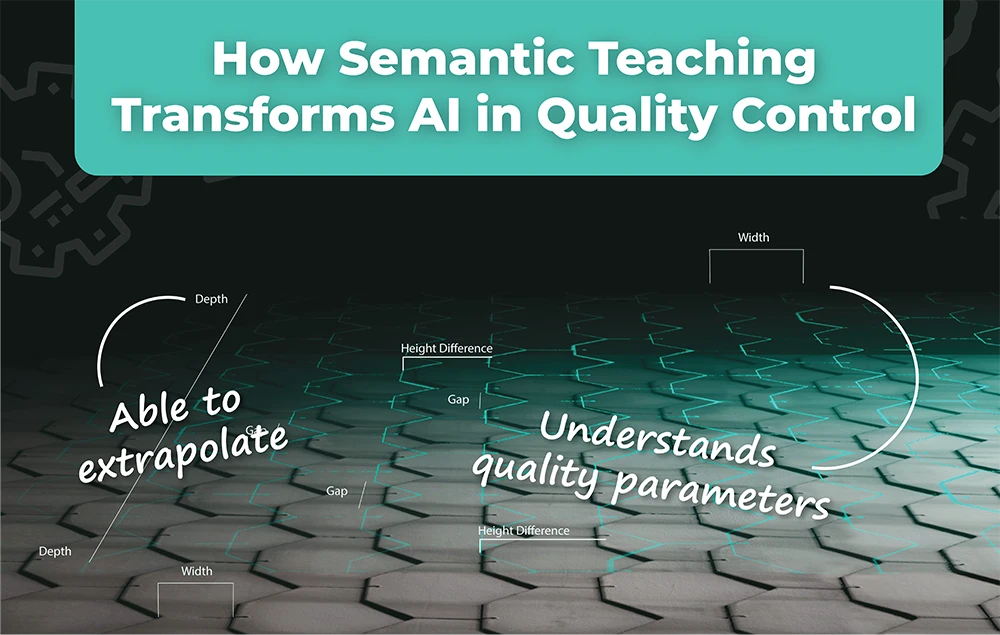

Traditional systems need thousands of labelled examples to grasp what’s right or wrong. Zetamotion’s approach is different: by combining semantic teaching with generative AI, we’ve built a highly efficient system where AI doesn’t just detect defects — it understands them. Imagine AI as a new apprentice on the factory floor, learning to spot defects under the guidance of an experienced inspector.

Take, for example, a scratch on a product. It may come in hundreds of different shapes, sizes and overall phenotypes. If it’s in a low-stress area, it may be harmless; if it’s in a crucial spot, it could impact performance, and so on. Where traditional AI would require fully labelled examples for each such variant, our semantic teaching enables AI to recognize this kind of context, allowing for quality control that’s accurate and nuanced. This understanding allows manufacturers to maintain reliable, high-accuracy inspection, even as product specifications change over time.

Zetamotion’s AI Assistant: A Collaboration of Human and Machine Insight

At Zetamotion, we believe in combining human expertise with AI’s efficiency. Our AI Assistant works alongside human inspectors, continuously refining the general AI system’s semantic understanding based on real-world input. This collaboration allows the Assistant to enhance the system’s semantic teaching, learning from human feedback to better interpret defects in context and make accurate, meaningful decisions.

By leveraging this human-AI partnership, manufacturers gain the benefits of automation without sacrificing the nuance that human insight provides. As a result, quality control becomes faster and more reliable, reducing the need for extensive manual oversight and enriching the AI’s ability to make informed decisions.

Just One Scan with Spectron™: Streamlining Onboarding Without Manual Labelling

In quality control, one of the toughest challenges is keeping up with products that aren’t uniform — especially in agile manufacturing, where designs and materials change frequently. Traditional machine vision systems often fall short here, needing vast, carefully labelled datasets to recognize every possible variation. This approach isn’t practical for manufacturers working with a variety of designs or materials.

Spectron™ offers a refreshing alternative. With synthetic data generation, our software creates robust datasets from just a single scan, adapting effortlessly to diverse product variations without labour-intensive labelling. This flexibility is invaluable for inspecting non-uniform products, like roof shingles, where every piece looks slightly different. With its semantic understanding, Spectron™ doesn’t just detect defects — it understands their importance, delivering accurate inspection even when every item is unique.

For example, one of our clients was struggling with an outdated inspection system that couldn’t handle new product variations without costly reconfigurations. Switching to Spectron™ allowed them to bring these new variations online smoothly, all while maintaining exceptional accuracy. This adaptability is just one of the reasons our software empowers manufacturers to keep their production lines agile and efficient, no matter how complex their products may be.

Conclusion: Shaping the Future of AI Quality Control with Semantic Teaching and Synthetic Data

At Zetamotion, we’re reshaping the future of automated quality control with a unique combination of semantic teaching and synthetic data. These technologies empower manufacturers and inspection companies with a scalable, adaptive solution that maintains high accuracy without the need for manual labelling. Through Spectron Graphics™ and Spectron ML™, our AI systems are ready to deploy with minimal setup time, helping manufacturers save resources and achieve reliable quality control.

Our approach gives manufacturers a clear path to near-perfect accuracy in defect detection, supporting dynamic product lines with minimal intervention. By focusing on semantic teaching and synthetic data, Zetamotion offers a robust, agile system that can evolve with your operations.

Ready to revolutionise your inspection process with AI-powered inspection solutions? Our Spectron™ and AI Assistant are here to help. Contact us today to learn how semantic teaching and synthetic data can elevate your quality control, allowing your operations to scale effortlessly and effectively.