Artificial Intelligence is transforming industries worldwide, with manufacturing at the forefront. From boosting efficiency to enhancing quality control, AI’s impact on manufacturing is increasingly significant. Today, we have the pleasure of discussing this with Prof. Dr. Edward Krubasik, a leading expert in the field.

With an impressive background in nuclear physics and an MBA, Prof. Dr. Krubasik has over two decades of experience at McKinsey in high-tech industries and manufacturing. He also served on the Siemens Executive Board for a decade, where he led industrial and mobility businesses. Currently, he chairs the Industrial Advisory Board at the Munich Institute of Robotics and Machine Intelligence (MIRMI) and mentors AI and climate-focused startups.

In this interview, we’ll delve into how AI is reshaping manufacturing, the challenges it presents, and what the future may hold for this dynamic technology.

Welcome, Prof. Dr. Krubasik. We are delighted to have you with us today. To start, could you share your insights on how AI is revolutionising daily operations in manufacturing?

AI quality control systems give immediate online information on problems in the manufacturing line, helping to avoid delays through laboratory tests or due to finding out too late at the end of the line when valuable work in process has been added to defects. Immediate real time corrections are what manufacturers are looking for.

What do you consider the most significant challenges for manufacturers when implementing AI?

The main challenge, in my view, is a lack of understanding of it. Therefore, easy first applications and very fast economic payoff is the most convincing start with AI in manufacturing. Quality control AI systems offer such an opportunity.

Can AI-powered quality control contribute to sustainability in manufacturing?

Absolutely. AI in quality control can help save materials and energy by preventing waste from unusable work-in-process. It also reduces the need for rework and lowers the chances of customer rejects, all of which contribute to more sustainable manufacturing practices.

Adopting AI – what’s at stake if manufacturers get it wrong, or worse, if they do nothing?

Not adopting AI quality control systems comes with significant opportunity costs, such as expensive work-in-process going into the wastebasket, the cost of rejects and replacements, losing customers due to undetected defects in your product, and spending lots of unnecessary money on manual quality control. I would recommend starting with AI QC tools in situations where there is a clear and quick payback, often within just a few months.

You have witnessed other transformative technologies change the landscape of manufacturing. How does AI compare?

Indeed, automation systems have gradually evolved into indispensable tools in manufacturing, with additional solutions and software continuously being integrated, such as those from Siemens. Zetamotion QC AI Solutions could very well be the next step in this evolution, integrating seamlessly with these systems. I wouldn’t be surprised to see a Zetamotion AI QC solution in the Siemens Xcelerator marketplace in the near future.

What advice would you give to manufacturing companies hesitant about integrating AI-powered quality control?

I recommend starting with simple software applications that offer a quick return on investment. Quality control SaaS is an ideal entry point for companies new to AI.

Among other AI applications in the factory, what makes your solution stand out?

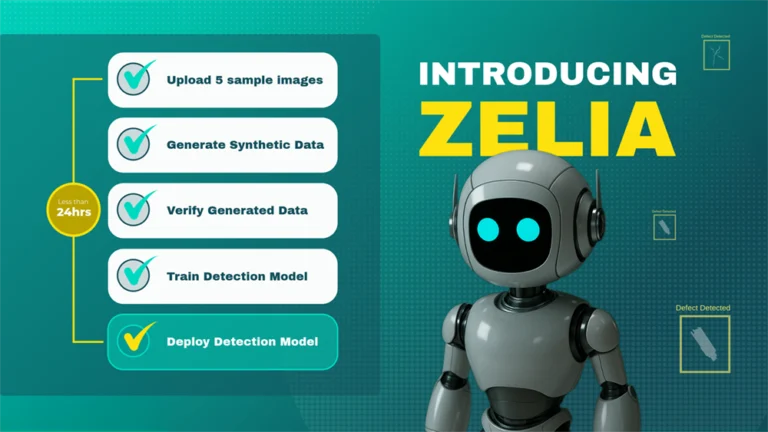

Our technology is easy to install and is one of the most powerful and user-friendly QC software and hardware systems available. In fact, even system OEMs sometimes request to have Zetamotion software integrated into their systems.

How have initial customers responded to your application results?

Our initial customers were very helpful in the interactive problem solving in the very first phase of installing the system. Helping the customer and learning from their input is one of Zetamotion’s key strengths.

What would you say to customers considering your technology?

Our technology has proven its effectiveness, particularly in the high-performance glass sector, and has achieved success in various proof-of-concept studies across different industries. The real-time, online, and inline quality control features have been especially valuable, while end-of-line QC stations have also demonstrated success.

Zetamotion continuously upgrades its technology, offering improved software to customers at regular intervals. We take pride in our initial support during system installation, staying on-site until the customer is fully satisfied.

Where is the economic value to the customer in applying your technology?

The most immediately visible economic value comes from reducing the loss of valuable already worked-on material, reducing work in process cost by immediate adjustments on manufacturing lines after alarms, and saving on QC personnel cost. Additionally, over time, customers benefit from improved satisfaction, reduced rejects and rework, fewer customer complaints, and the potential for increased orders.

What do you envision for the future of AI in quality control for manufacturing?

We expect that AI will take over most quality control functions in manufacturing. This includes providing real-time information on dashboards, raising alarms based on user-defined event levels, automatically integrating and analysing multiple QC points along a manufacturing line, and generating defect waterfall charts to identify and address problem causes.