From Samples to Smart Models

Spectron’s curated AI training pipeline gets you to accurate inspection in under 2 weeks from just a few samples. We take care of everything from synthetic data generation to AI model training.

Meet ZELIA: Your New AI Quality Inspection Assistant

Discover the new Zetamotion pipeline & assistant that turns a few sample images into a fully curated synthetic dataset and trains your AI vision inspection model for you. Faster, adaptive, and effortless.

Sample Collection & Defect Catalogues

You provide real production samples or visuals from past defects.

Can be in the form of your standard defect catalogue.

This forms the foundation of your inspection logic and defect taxonomy

Synthetic Data Generation & Curation

Automatically generates photorealistic defects across sizes, densities, lighting, and materials

Covers variability that doesn’t show up in limited real-world samples

No manual labeling needed—our pipeline handles it all

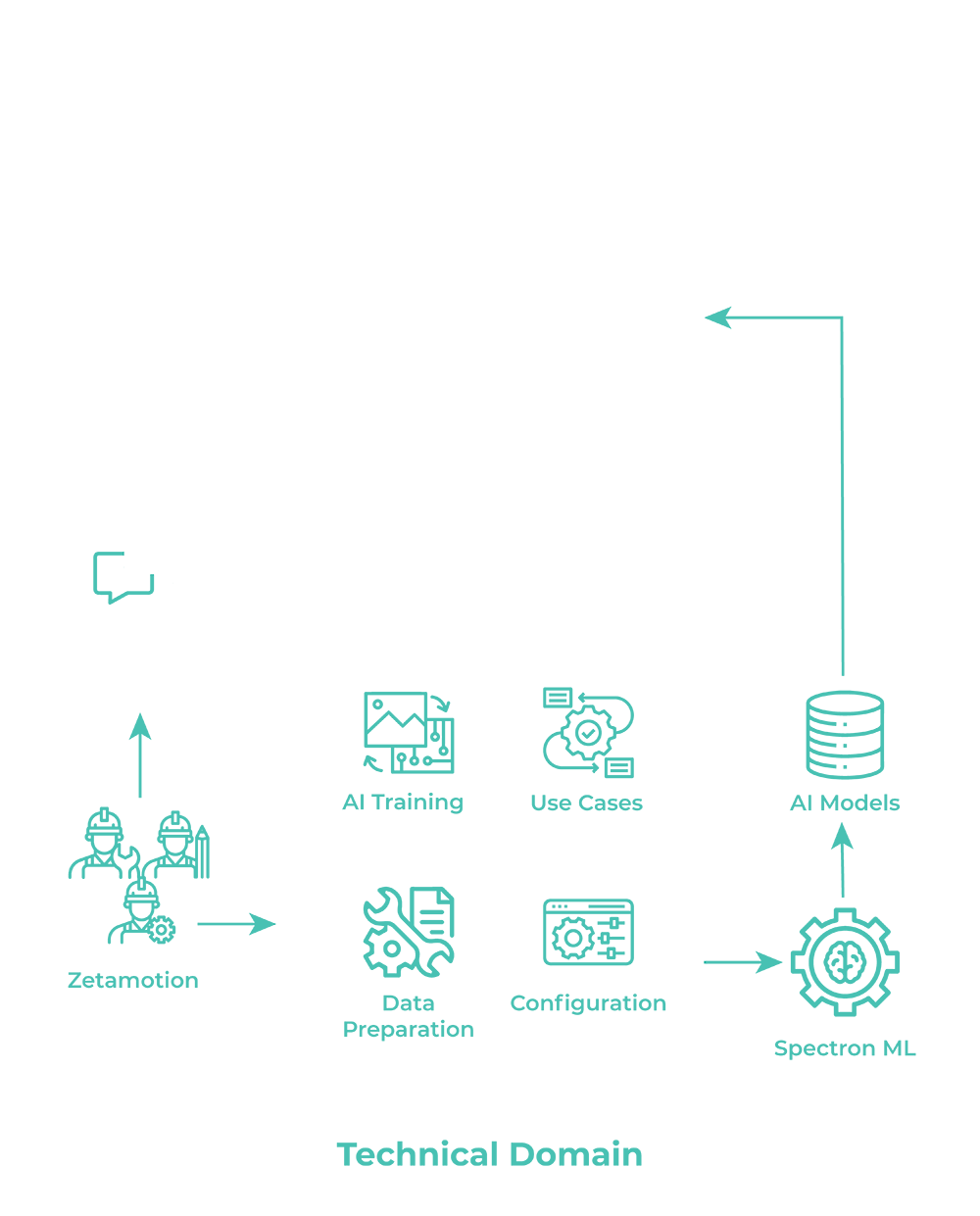

Synthetic DataAI Model Training

Trained by our in-house vision experts and PhDs

Defect detection model tailored to your product, using the curated dataset.

Ready for inspection in under 24 hours per product variant

We Handle the Data, So You Don’t Have To

Spectron’s AI doesn’t just detect defects, it understands your products.

Our system is built to make AI quality inspection deployable, reliable, and scalable. At the core is our synthetic data engine, which allows us to train production-ready models from just a single good part scan. No need for thousands of manually labeled defect samples.

Your team doesn’t need to collect, clean, or annotate anything.

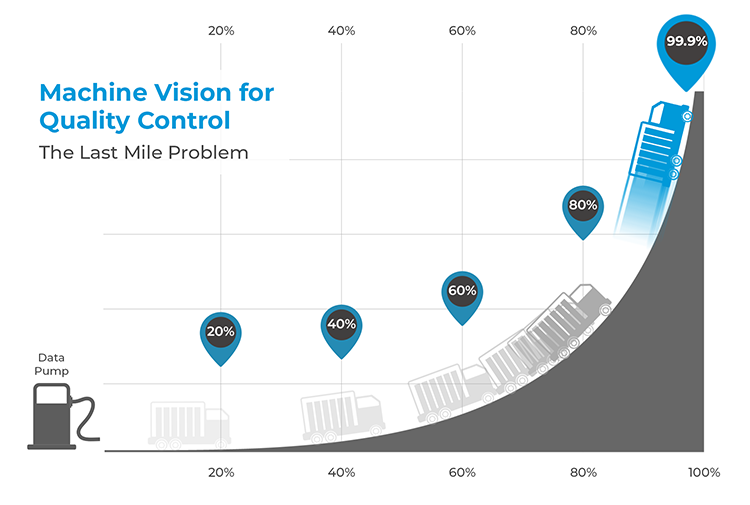

Fast to Deploy. Even Faster to Adapt.

Traditional AI systems stall at ~80% accuracy with massive effort. Spectron breaks that ceiling. Thanks to synthetic data and pre-trained visual intelligence, we can go from zero to production in under 2 weeks and continuously improve from there.

Pre-deployment feasibility checks

On-premise inference (no cloud dependence)

Plug-and-play with your existing cameras or compute stack

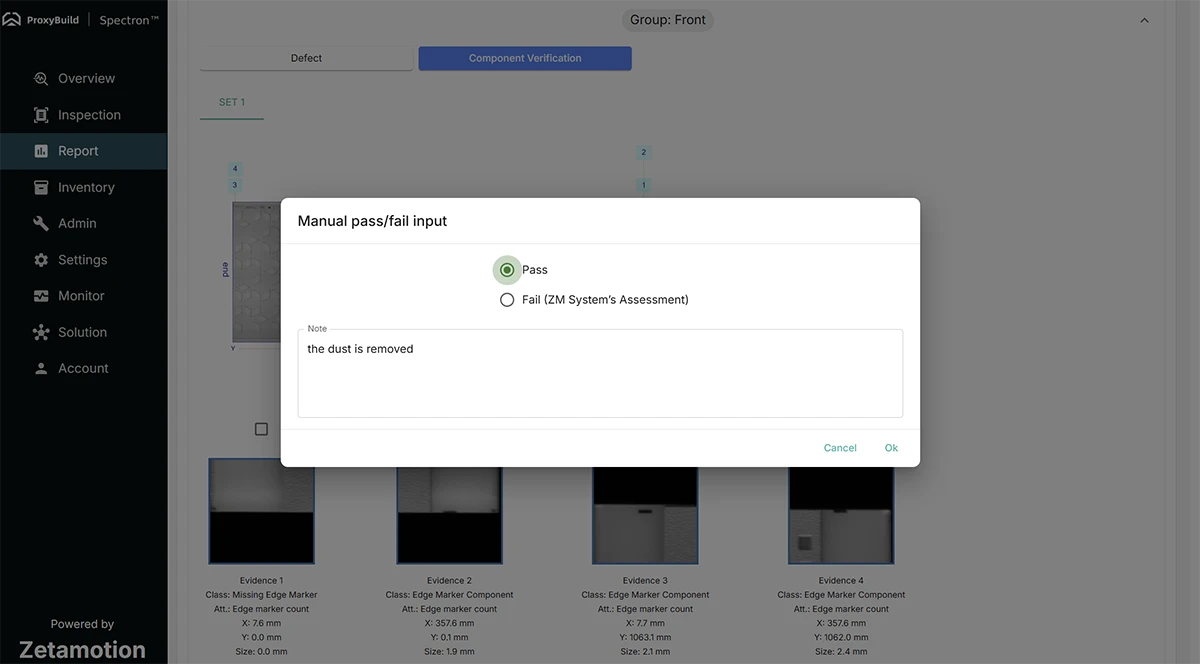

Synthetic dataHuman-in-the-Loop (HITL) Feedback

Engineers can accept/reject detections in real-world inspections

Feedback loops directly into retraining pipelines

Enables continuous improvement and confidence as new defect types emerge

Platform Configuration