The Challenge

Aviation Glass (AG) produces high-tech glass for aircraft interiors where an invisible scratch today could become tomorrow’s safety hazard. They needed to:

- Accelerate inspection without compromising quality

- Reduce manual-inspection labour costs

- Turn raw defect data into actionable process improvements, and

- Capture a full digital record of every panel

Why Spectron™

By deploying Zetamotion’s Spectron™ platform, AG moved from batch-based manual checks to in-line, AI-powered inspection. Spectron now scans each panel in seconds, not 20+ minutes , while its human-in-the-loop workflow lets engineers override, comment, and feed corrections back into the model for continuous learning.

Results at a Glance

| KPI | Performance | Impact |

|---|---|---|

| Inspection cycle time | 20 + min → Seconds | -99 % |

| Annual hours spent inspecting | 1 200 + hrs saved | Labour re-allocated |

| Product variants covered | 46 variants | Seamless scalability |

| Yield improvement | + 5 % | Higher throughput |

| Detection accuracy | 99.99 % | Fewer false rejects |

Visual Insights

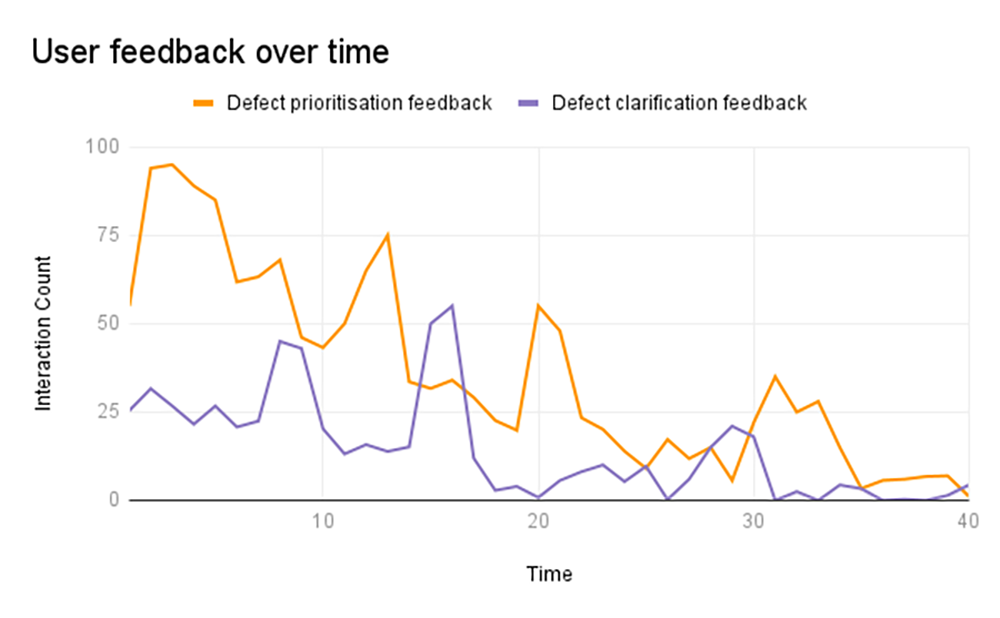

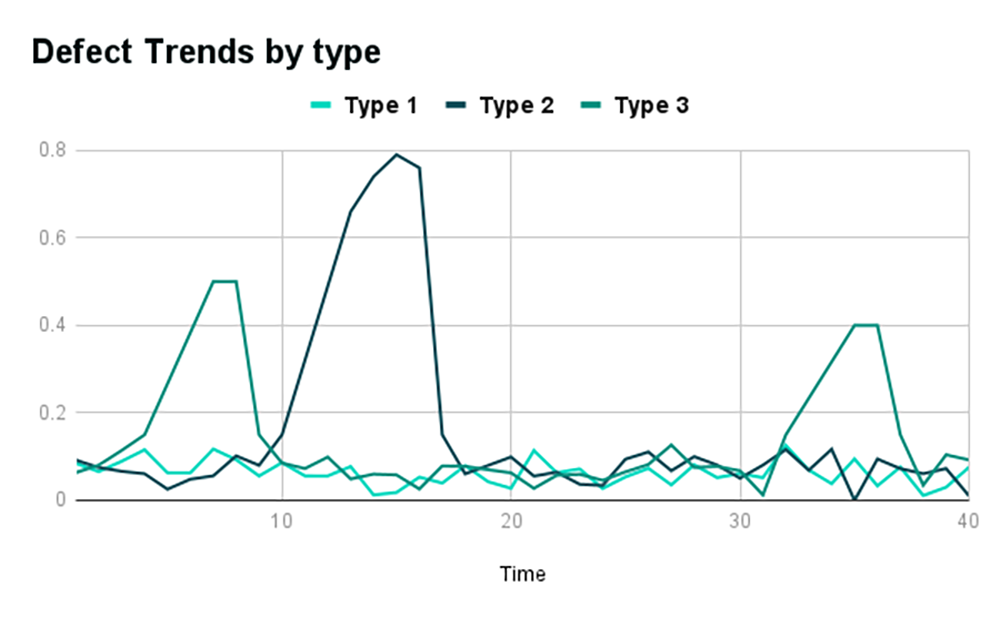

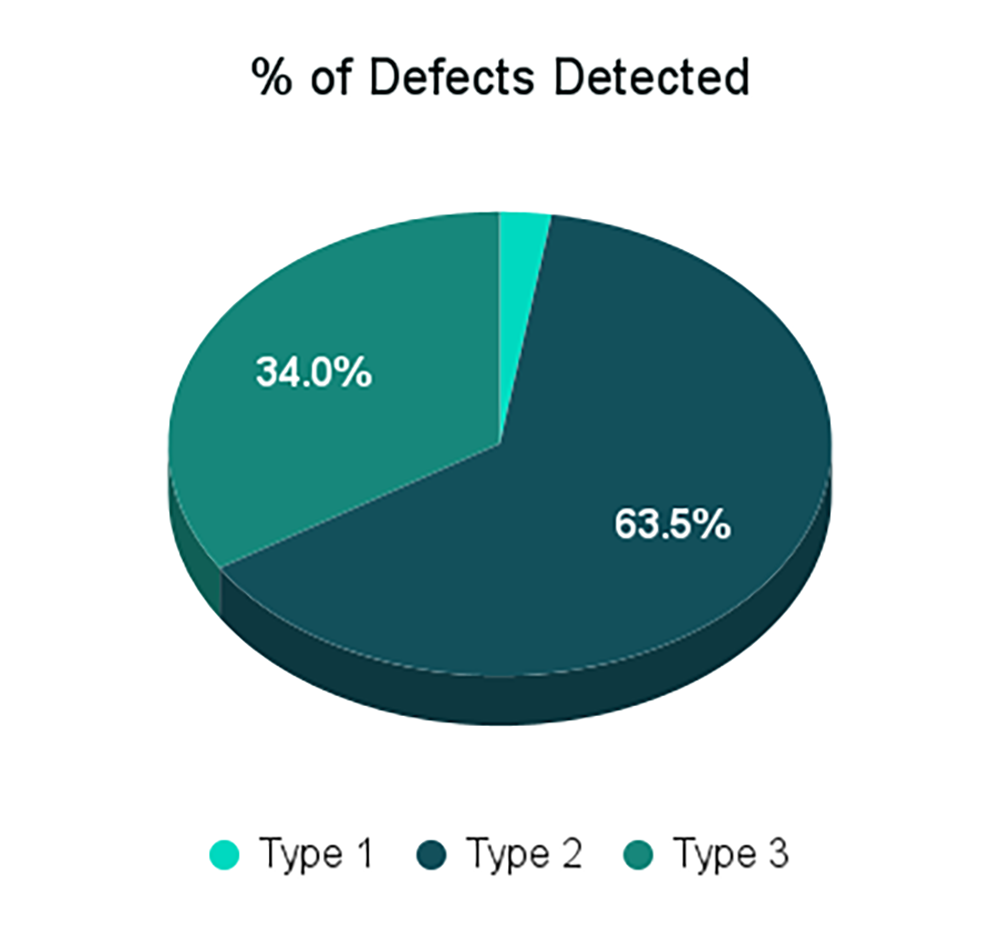

What the data says

- Type 2 defects dominate—63.5 % of all findings—pinpointing where engineers must focus root-cause analysis.

- Early human feedback sessions were intense but tapered off as Spectron’s accuracy climbed, showing successful knowledge capture.

- A mid-run spike in Type 2 anomalies prompted a quick camera-resolution upgrade that restored stability in < 24 hours .

Lessons Learned

- Agree on defect taxonomy first. Aligning on what “good” looks like reduced supply-chain friction

- Pair AI with human expertise. Spectron’s feedback loop kept rare but critical defect phenotypes in view

- Design for adaptability. A one-day camera upgrade proved the platform’s flexibility to evolving specs

Ready to Raise Your Own Quality Bar?

- Explore the Spectron™ platform

- Complimentary feasibility check for your line