Artificial intelligence (AI) has transformed many industries, yet misconceptions about AI-powered visual inspection can hold people back. Here, we address five common concerns and explain how Zetamotion’s technology makes quality control simpler and more reliable.

Preconception 1: You need machine vision experts to use AI

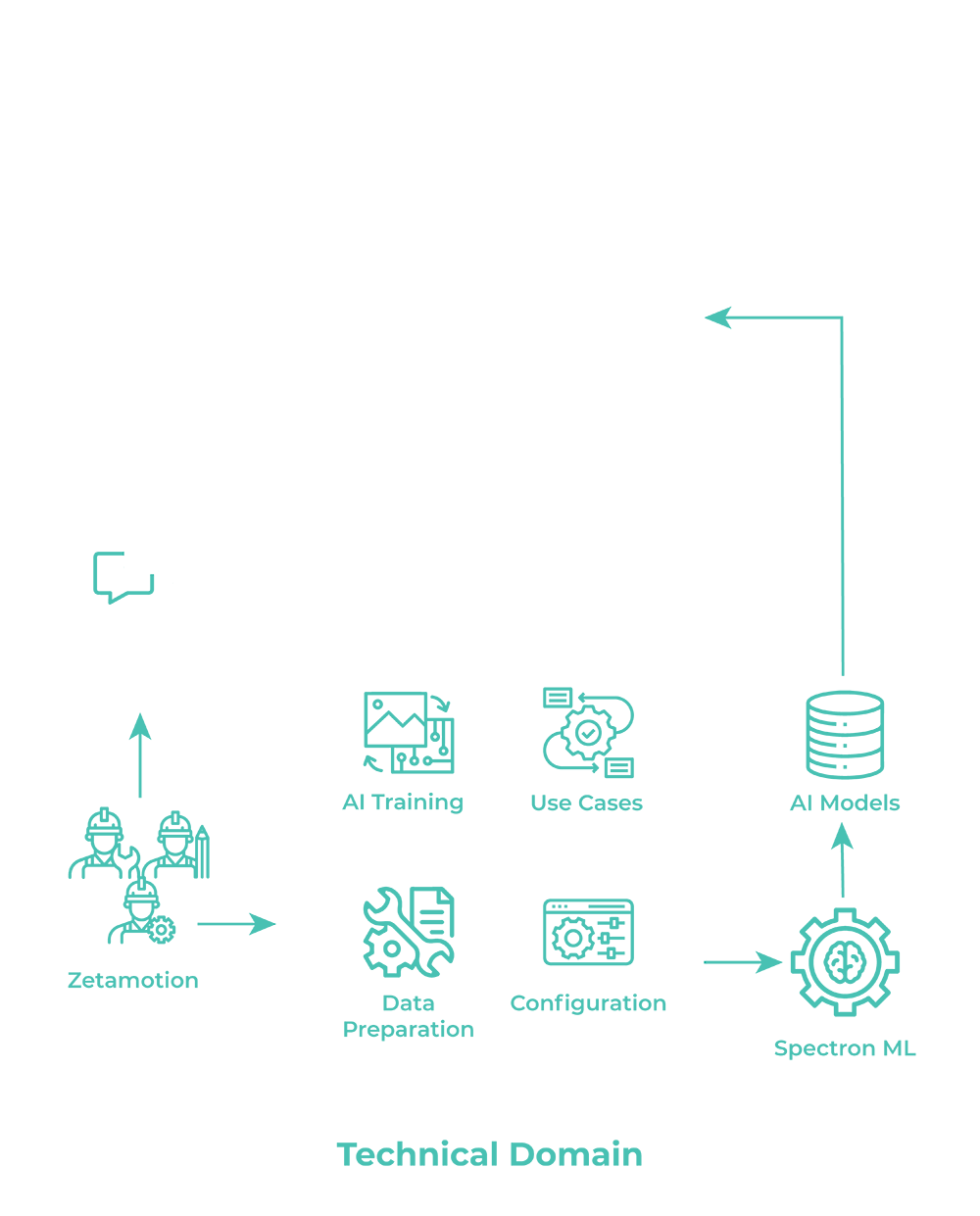

Fact: You don’t need a PhD. Our Spectron™ platform is designed to be user-friendly for operators of any skill level. With an intuitive interface and automated setup, you can get started quickly—and our expert team is always here to help.

Preconception 2: AI inspection is hard to install

Fact: Our solution integrates easily with a wide range of sensors and hardware. We work with you every step of the way, from selecting the right hardware to designing and deploying the perfect setup for your production line. It’s a smooth process with minimal disruption.

Preconception 3: AI inspection only works on non-reflective products

Fact: Reflective or shiny surfaces? No problem. Spectron™ uses our proprietary Spectron Graphics™ technology to handle challenging materials — from light-absorbing bitumen to shiny metals and transparent glass. This means reliable inspection across a wide variety of products.

Preconception 4: Maintaining AI systems is a lot of work

Fact: Our platform is built for easy maintenance. With a straightforward calibration and validation process supported by a mutually agreed Measurement Systems Analysis (MSA), you don’t have to worry about constant manual adjustments. Spectron™ offers flexible deployment — on-premise or via secure cloud — and features self-monitoring and seamless updates to keep your system running smoothly.

Preconception 5: Every new use case requires starting from scratch

Fact: Not with us. Spectron™ generates synthetic datasets from a single scan, allowing you to scale quickly across different product lines without tedious reconfiguration. Our semantic teaching technology ensures high accuracy and adaptability, saving you time and resources.

The Reality: Perfect Data, Perfect Products

At Zetamotion, we’re all about breaking down the barriers to AI adoption. Our solutions are built to simplify and enhance quality control while scaling with your needs. Whether you’re dealing with reflective materials or complex, multi-product environments, Spectron™ is designed to help you achieve consistent, high-quality production.

Contact us today to find out how Zetamotion can improve your production efficiency.