We’re proud to share that Zetamotion was recently featured in JEC Composites Magazine (Issue 163, July–August 2025), highlighting how the composite industry is moving from manual inspection to AI-driven quality control. Read the full feature in JEC Composites Magazine.

The article explores why composites—despite their strength and advanced properties—have remained difficult to inspect using traditional machine vision. Conventional systems often misinterpret fibre placement, surface variations, or glare, forcing manufacturers to rely on human eyesight. This creates bottlenecks and inconsistencies in production.

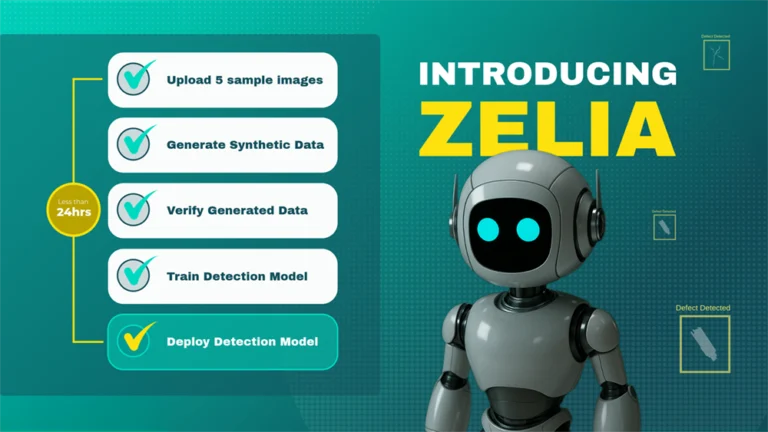

AI-driven quality control is now changing the equation. Instead of depending on large labelled datasets, platforms like Spectron use curated synthetic training data to interpret complex surface geometries and detect subtle variations. The result is inspection that does more than see defects—it understands context.

The feature also notes how this impacts factory floors. With AI handling inspection, technicians can focus on root-cause analysis and process improvement rather than repetitive flaw detection. The ripple effect is increased traceability, faster cycle times, and more confidence in inspection results.

Importantly, the shift doesn’t replace skilled workers—it supports them. AI lifts the burden of repetitive inspection, enabling teams to apply their expertise where it matters most. For manufacturers, this means scalable, objective, and future-proof quality systems.

To explore these insights in full, see the complete article in JEC Composites Magazine Issue 163.