In a recent Quality Digest feature, “Smarter Quality Control: How Synthetic Data and AI Are Revolutionizing Manufacturing Efficiency,” author Wilhelm Klein lays out how manufacturers aIn a recent Quality Digest feature, Wilhelm Klein explored how synthetic data and AI are reshaping the future of manufacturing quality control. The article highlights why many manufacturers struggle to move from “good enough” defect detection to the near-perfect accuracy demanded by modern production. Read the full article here.

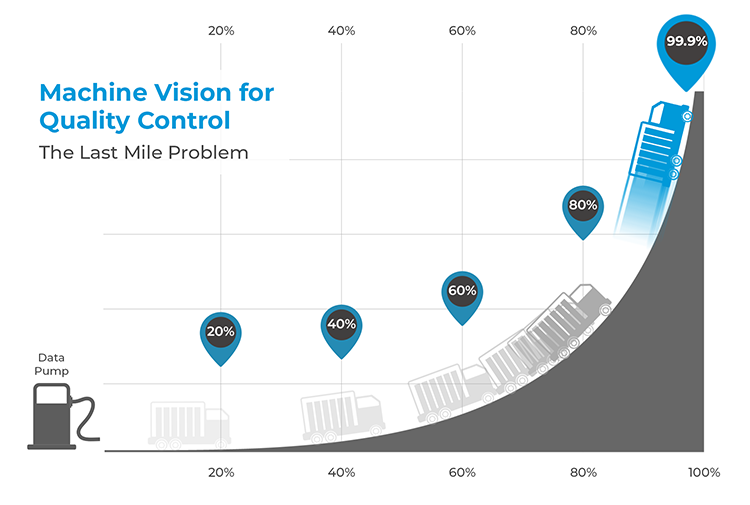

The biggest challenge is the “last mile” of inspection—pushing systems from around 80 percent accuracy to 99.9 percent. Achieving this requires vast data and fine-tuned inspection capabilities. Synthetic data fills a critical gap by generating realistic defect examples when actual samples are rare or expensive. This accelerates model training and helps inspection platforms catch edge-case anomalies.

The benefits extend beyond accuracy. Smarter inspection directly reduces waste, improves production yields, and lowers energy consumption. Manufacturers gain both financial and sustainability advantages—goals that are increasingly inseparable in today’s industrial landscape.

At Zetamotion, we see these same dynamics in action. Our Spectron platform uses AI to adapt quickly to new products, delivering high accuracy with minimal data requirements. By combining synthetic data with self-learning algorithms, manufacturers can bypass traditional bottlenecks and unlock faster ROI. For those exploring whether vision automation is right for their lines, our manufacturing inspection service offers a practical way to start.

To explore the broader industry perspective, see the full Quality Digest article: Smarter Quality Control: How Synthetic Data and AI Are Revolutionizing Manufacturing Efficiency.