When we talk to manufacturers about deploying AI-based inspection, the same roadblock comes up again and again: data. Collecting enough real-world defect images to train inspection AI can take months, sometimes years. And every new product variant resets the clock.

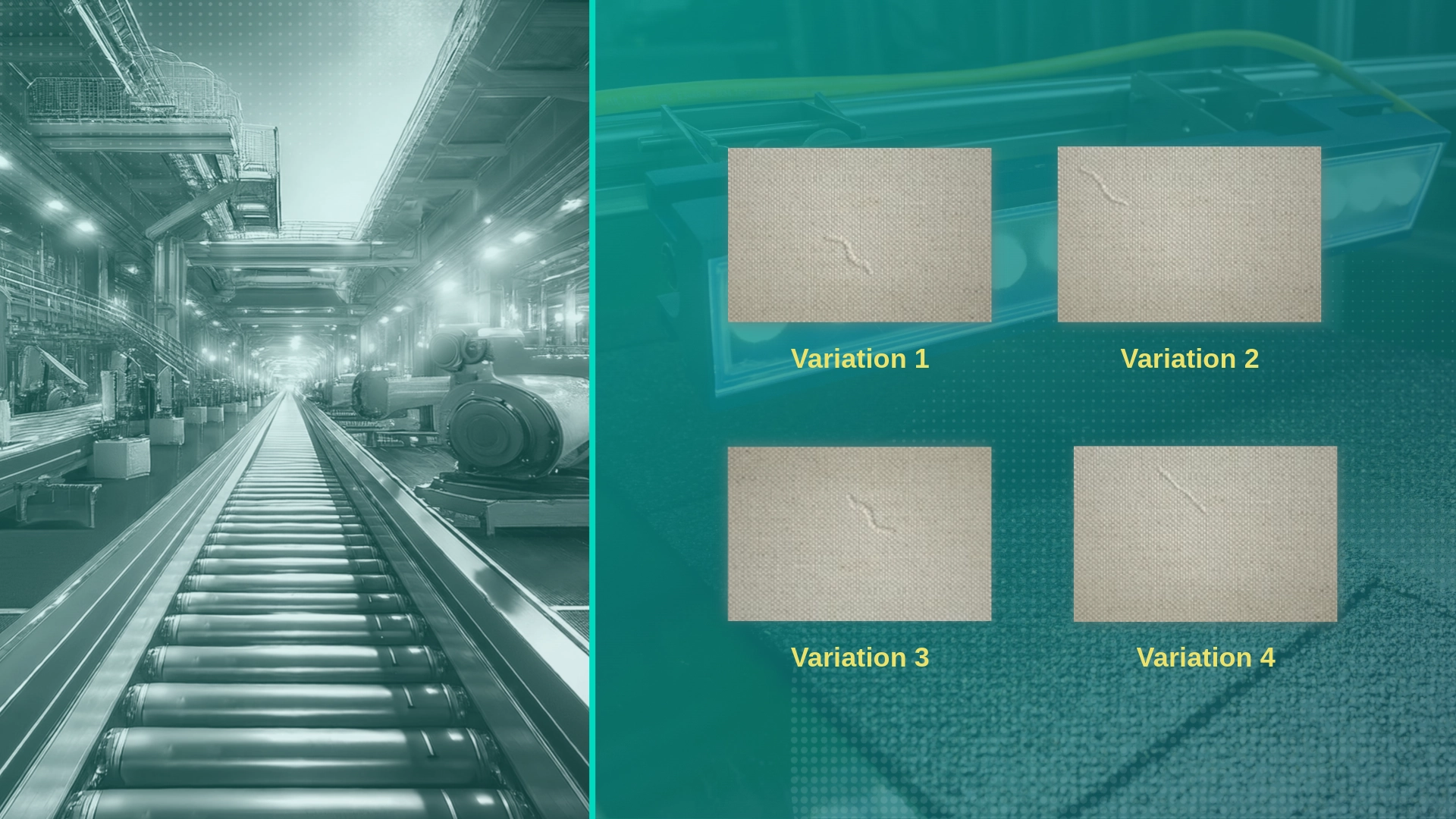

This bottleneck is especially painful in industries working with composite glass panels—like aerospace interiors or high-end automotive. These panels are layered with glass, resins, fibers, coatings, and decorative prints. Defects can be as small as a bubble or as complex as a fiber overhang. Capturing thousands of examples of every defect across hundreds of variants is not just impractical—it’s impossible.

So how do you build an AI inspection system that can spot everything from a dust inclusion to a micro-crack, without waiting on years of defect data? The answer is synthetic data.

The Traditional Bottleneck: Real Data at Real Cost

Imagine a plant producing 100 variants of laminated glass trim panels. To train a conventional inspection AI:

- You’d need over 1,000 images per variant

- Every image would require manual labeling

- Edge cases would still slip through

- And if a new panel design was released next week—you’d start from zero

This explains why so many manufacturers are stuck with 80–90% accurate inspection. The last 10%—the “last mile” to perfection—is blocked by the sheer scale of data collection.

The Synthetic Shift: From Weeks to Hours

Zetamotion’s Spectron™ platform solves this bottleneck by generating synthetic data. Here’s how it worked in practice:

At Aviation Glass, a producer of ultra-thin laminated panels for luxury aircraft, we onboarded a new panel design with a single scan. Over the course of the pilot, Spectron scanned 1,045 panels, saving more than 500 hours of manual inspection time and identifying over 42,000 defects with verified precision.

This is the power of synthetic data: scaling quality control across hundreds of panel variants without scaling the cost of data collection.

Why Synthetic Data Matters in Quality Inspection

When you eliminate the data bottleneck, you unlock the real potential of automated inspection:

- Speed to deploy: New product variants are ready for inspection in less than 24 hours

- Scalability: Move from a single line to entire factories without new data collection overhead

- Smarter edge-case detection: AI doesn’t just see “typical” defects—it learns from thousands of generated variations

- Consistency across shifts: No more relying on subjective human judgment; every panel is held to the same standard

This is particularly crucial in sectors like aerospace and automotive, where visual perfection is as critical as structural safety. With synthetic data for quality inspection, you no longer compromise between speed and accuracy—you achieve both.

Beyond “Good Enough”

Industrial quality control has lived too long with the idea that 80% or 90% accuracy is acceptable. But when a bubble in a composite glass panel can delay aircraft delivery or cost millions in recalls, “good enough” is not good enough.

By generating synthetic datasets that reflect thousands of potential defect conditions, Zetamotion’s Spectron doesn’t just improve inspection—it redefines it. Manufacturers get perfect data that creates perfect products.

And that’s why synthetic data isn’t the future. It’s the fix.