Do You Really Need to Define Every Defect? Zetamotion Debunks a Common AI Myth

In this insightful webinar, Dr. Wilhelm Klein, CEO of Zetamotion, challenges one of the biggest myths in AI-based quality inspection: that you must define all defect parameters in advance to get started.

Instead, he introduces the concept of defect consensus—the idea that defining every edge case upfront is often impossible, and unnecessary. Zetamotion’s Spectron™ platform enables manufacturers to begin with rough specifications and refine defect definitions collaboratively over time.

Whether you’re operating across multiple supplier sites or managing visual inspection for complex surfaces, this session offers a practical framework for achieving consistency and scalability in automated QC without perfection from day one.

🔍 Key Takeaways:

- Why the “perfect definition” mindset slows down AI deployment

- How Spectron enables shared defect understanding with visual segmentation tools

- What makes human inspection inconsistent—and how AI addresses it

- Real-world case study: coated panels in aerospace supply chains

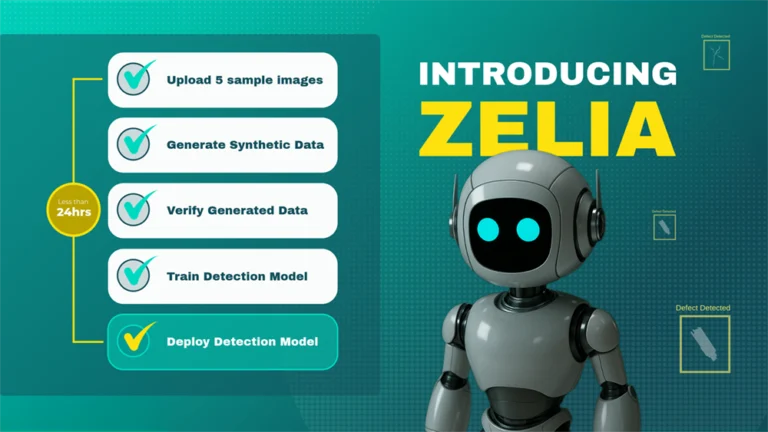

- How to start implementing AI inspection with minimal initial data

If your team is stuck waiting for the “perfect defect catalog,” this webinar is your sign to start iterating—because consistency doesn’t come from documents, it comes from shared, standardized visual data.