5 Preconceptions About AI-Based Visual Inspection – Debunked

When it comes to AI-powered quality control, the gap between what people expect and what they get can be big. Many manufacturers start AI projects with high hopes. They imagine a smooth rollout and instant improvements. However, the reality is often different. They face costly pilot failures. They run into data requirements that are unrealistic. In many cases, systems cannot handle the variation in real production lines.

This happens for a reason. AI in manufacturing is still a growing field. Often, tools are built for ideal lab conditions. Once they meet the noise, changes, and speed of a real factory, they struggle. As a result, businesses get stuck and lose trust in the technology.

In this webinar, the Zetamotion team takes on the five most common myths about AI in manufacturing quality control. We not only explain why these myths exist but also show why they are wrong. More importantly, we share how to move past them. The goal is simple: help manufacturers reach accuracy and scale without wasting years on trial and error.

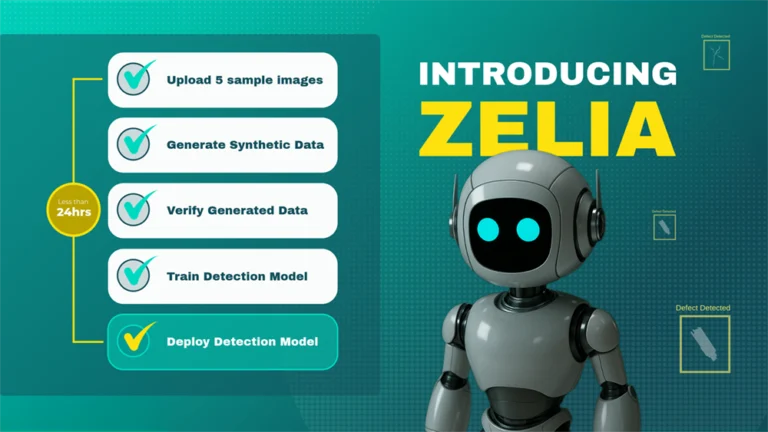

For example, one belief is that AI needs thousands of real-world samples before it works well. Similarly, another assumption is that reflective materials—like polished metal or glass—are almost impossible to inspect. Yet, these ideas are outdated. Instead, we show how synthetic data is changing the game. In fact, it lets AI models learn quickly without huge datasets. As a result, you can achieve high accuracy from just one scan.

💡 You’ll learn:

- Top 5 myths about AI in visual inspection—debunked

- Why machine vision struggles to scale with real-world variability

- How synthetic data eliminates massive data and labeling requirements

- Use cases: roof shingles, aerospace composites, reflective surfaces

- How Spectron simplifies installation and integrates with existing systems

The webinar is led by Dr. Wilhelm Klein, CEO of Zetamotion. Throughout the session, he combines technical insight with practical advice so the information is easy to follow. Because of this approach, you do not need to be an AI expert to understand the steps. The focus is on real solutions that you can use right away.

In addition, you will see how Spectron™ works with different hardware. We also explain how it handles multi-part inspection and adapts to unique production needs. Most importantly, it does all this without requiring a team of PhDs to run it.

For manufacturers exploring AI for the first time, this session is a guide to avoid common mistakes. On the other hand, for those who have already tried and failed, it offers a way forward. Meanwhile, for businesses looking to scale quality control across many sites, it shows how to do it without long delays.

“If your first AI pilot failed, it’s not your fault—most tools leave you doing the hard part. We don’t.” — Dr. Wilhelm Klein

💡 Bonus: Dive deeper with our part 2 to learn advanced methods for busting myths and getting real results.